Starch from corn

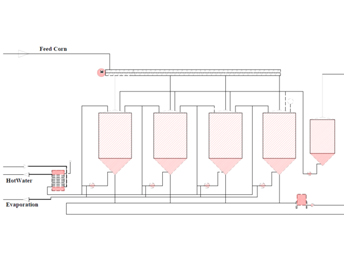

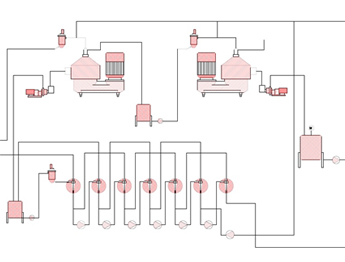

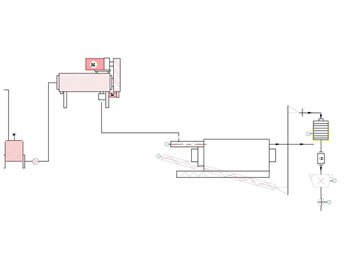

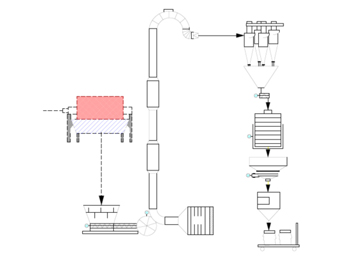

Corn starch process flowchart:

The following flowchart provide a brief overview of the main corn starch production process. To see the flow chart please click on….

Corn starch process description:

For obtaining starch from corn , the important thing is to release the starch from the cell structure in particular, without damaging the germ and thus to obtain extracted corn starch with minimum possible fat content.

The main mature process for corn starch production called wet-milling process. The goal of corn wet-milling process is to change corn into its four main components, starch, fiber , germ and gluten, then convert the components into useful products.

Below we tried to explain corn starch production process in more details , for more technical information on the process, please call MICROTEC process engineers.

1- Corn Cleaning and Steeping

Received corn must be cleaned to ensure it is free of dust, sand, metal and other impurities. After cleaning, it is soaked in water at a certain temperature around 50˚C for around 42 hours. During steeping, the kernels absorb water and get more than double in size. The gluten bonds in the corn loosen and starch is released. The water that the corn soaked in, referred to as steep-water, contains much of the soluble material from the corn, including a significant percentage of proteins and sugars. The corn after steeping is ready for further process.

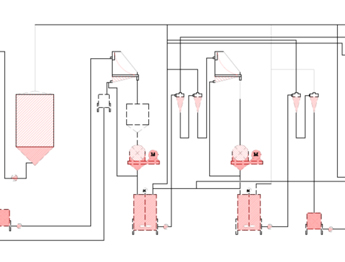

2- Milling ,Germ separation and drying

The corn is coarsely milled in disc mills to separate the germ from starch, gluten and fiber. This generally happens in two stages. Each stages gave been designed to separate germ for other corn components. Two disc mills are employed for this purpose along with two germ separation hydro cyclones to separate germ with no damage.

The corn is coarsely milled in disc mills to separate the germ from starch, gluten and fiber. This generally happens in two stages. Each stages gave been designed to separate germ for other corn components. Two disc mills are employed for this purpose along with two germ separation hydro cyclones to separate germ with no damage.

The corn germ, which contains corn oil, is removed from the slurry u and washed then, dewatered using germ screw press. It is then dried and sold for further processing to recover the oil or as animal feed

3- Grit milling and fiber washing

The corn grit passing the underflow of the second germ hydro cyclone unit is pre-dewatered on gravity arc screen. The screened off milk flows directly as mill starch milk to starch / gluten separation.

The corn grit passing the underflow of the second germ hydro cyclone unit is pre-dewatered on gravity arc screen. The screened off milk flows directly as mill starch milk to starch / gluten separation.

The fine milling is done by a special mill which performs an effective grinding of the harder portions of the corn. It should free the starch nearly completely and keep the fiber as coarse as possible to facilitate the following fiber washing and dewatering. The grit milk containing coarse and fine fiber is pumped to the first bin of the multi-compartment fiber washing tank system and from there through a 7-stages pressure arc screen system for starch extraction and counter current fiber washing. Washed fiber leaves the system and is dewatered using fiber screw press and then dried. But starch milk flows to starch and gluten separation unit.

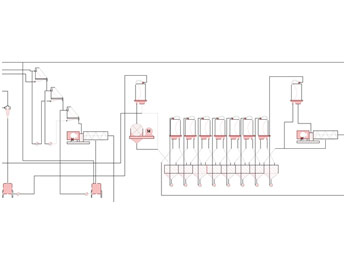

4- Starch and gluten separation and starch washing

The mill starch milk from grit milling and fiber washing is free of germs and fiber, but still contains besides Starch granules suspended material as insoluble protein (gluten), fat and hemicellulose materials. Furthermore soluble and colloids are in the starch milk.

The mill starch milk from grit milling and fiber washing is free of germs and fiber, but still contains besides Starch granules suspended material as insoluble protein (gluten), fat and hemicellulose materials. Furthermore soluble and colloids are in the starch milk.

Starch & gluten is fed to a disc separator. The purpose is to separate starch from gluten. Starch leaves the separator as under flow and gluten leaves it as overflow. Starch then goes to a starch washing hydro cyclone for more purity and concentration while starch goes to gluten concentrator.

5- Gluten dewatering and drying

The gluten from disc separator contains the insoluble gluten and the soluble, but is free from starch. The insoluble gluten has to be concentrated in a nozzle separator before the gluten can be dewatered.

The gluten from disc separator contains the insoluble gluten and the soluble, but is free from starch. The insoluble gluten has to be concentrated in a nozzle separator before the gluten can be dewatered.

In the disc nozzle separator the gluten is concentrated as heavy phase and leaves via nozzles whereas the soluble leaves with the water as light phase (overflow) via a centripetal pump.

Concentrated gluten is fed to a centrifugal decanter or rotary drum filter for dewatering before drying by a tube drying system.

6- Starch dewatering and drying

The refined starch slurry is dewatered by means of a specially designed peeler centrifuge or rotary drum filter. The dewatered starch cake is sent to the drying section and is dried using a flash drying system specially designed for starch drying

The refined starch slurry is dewatered by means of a specially designed peeler centrifuge or rotary drum filter. The dewatered starch cake is sent to the drying section and is dried using a flash drying system specially designed for starch drying

What our Customers say

What our Customers say