Fructose from Starch

Fructose Production Process Flowchart:

The following flowchart provides a brief review to the main Fructose production processes steps. Please click here to see the flowchart.

Fructose Production Process Description:

Here is a brief description of Fructose syrup production process:

1- Liquefaction

The aim of the liquefaction process is to convert the starch slurry into liqueur by breaking the starch molecules with enzyme under determined temperature, pressure and reaction time.

The aim of the liquefaction process is to convert the starch slurry into liqueur by breaking the starch molecules with enzyme under determined temperature, pressure and reaction time.

2- Saccharification

In this step, Glucoamylase enzyme or another type of enzyme is used to complete the breakdown of starch into dextrose. The amylase is added immediately and the slurry is pumped into Saccharification tank. It takes about 40 hours for Saccharification. When the Saccharification liquid reaches the required DE value, it is heated to 70℃ immediately.

In this step, Glucoamylase enzyme or another type of enzyme is used to complete the breakdown of starch into dextrose. The amylase is added immediately and the slurry is pumped into Saccharification tank. It takes about 40 hours for Saccharification. When the Saccharification liquid reaches the required DE value, it is heated to 70℃ immediately.

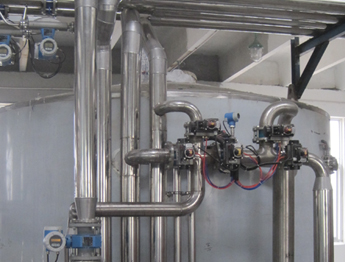

3- Primary and Membrane Filtration

Before entering to MEMBERANE SYSTEM, glucose is filtered from slags created during liquefaction and scarification process. Saccharified solution containing several organic compounds (for example: proteins, fatty substances, not liquefied starch, long chain polysaccharides, fatty acids, protein and fiber). The traditional method for removing these impurities was using activated carbon and diatomaceous earth and filtrating them using filter press and rotary vacuum filter. But new technology is using MEMERANE FILTERATION

Before entering to MEMBERANE SYSTEM, glucose is filtered from slags created during liquefaction and scarification process. Saccharified solution containing several organic compounds (for example: proteins, fatty substances, not liquefied starch, long chain polysaccharides, fatty acids, protein and fiber). The traditional method for removing these impurities was using activated carbon and diatomaceous earth and filtrating them using filter press and rotary vacuum filter. But new technology is using MEMERANE FILTERATION

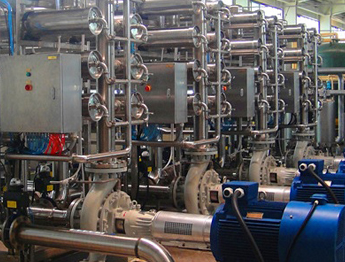

4- First Ion Exchanging

When the liquid is cooled down to below 50℃, it is fed to the ion exchange system. Ion exchangers are cation and anion ion-exchanger.

When the liquid is cooled down to below 50℃, it is fed to the ion exchange system. Ion exchangers are cation and anion ion-exchanger.

5- First Evaporation

The refined liquid then comes to the evaporator to be concentrated to the required value. Then, it is pumped to the final product tank or going to the next stage of HFCS 55 production. Generally two kinds of evaporators are used for this section for glucose concentration, Falling film evaporator and plate evaporator.

The refined liquid then comes to the evaporator to be concentrated to the required value. Then, it is pumped to the final product tank or going to the next stage of HFCS 55 production. Generally two kinds of evaporators are used for this section for glucose concentration, Falling film evaporator and plate evaporator.

6- Isomerization

Isomerization system is the key component of the Fructose line. It is used to produce Fructose 42 from Glucose. Enzymatic method and controlled temperature and important parameters are very important Fructose 42 production.

Isomerization system is the key component of the Fructose line. It is used to produce Fructose 42 from Glucose. Enzymatic method and controlled temperature and important parameters are very important Fructose 42 production.

7- De-colorization and second demineralization

HFCS 42 demineralization happens at this step

HFCS 42 demineralization happens at this step

8- Second Evaporation

HFCS 42 is getting concentrated using evaporator at this stage

9- Chromatography Separation and carbon filtration

Chromatographic is a new technology of continues separation and purification in HFCS 55 processing line for separation of Glucose and Fructose

Chromatographic is a new technology of continues separation and purification in HFCS 55 processing line for separation of Glucose and Fructose

10- Sterilization and FHCS 55 Evaporation and storage

Final refined and de-colored HFCS 55 goes to Mutli-effect evaporator for concentration and then for storage.

Final refined and de-colored HFCS 55 goes to Mutli-effect evaporator for concentration and then for storage.

What our Customers say

What our Customers say