Gluten Ring Dryer

Applications:

- Gluten drying in wheat starch processing line

Features and benefits:

- Multi or single stage classifier

- Minimizing required airflow

- Prevent thermal damaging of gluten

- Indirect air heating

- High efficiency and short drying time

- Low maintenance

- Control over particle size and fine powder quality

Description:

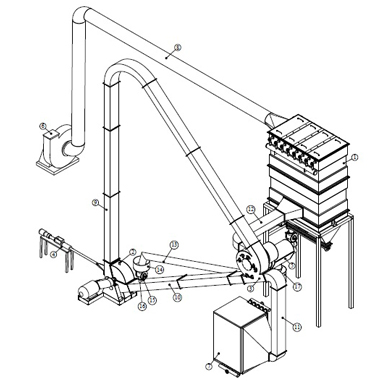

Gluten Ring Dryer is defined like a starch flash dryer as the drying of particles that are suspended and conveyed in a hot air stream. The main difference between Gluten ring dryer and a flash dryer system which is used for starch drying in starch industry is presence of gluten classifier in Ring dryer. The principle of Ring Dryer is also to evaporate surface moisture instantaneously. It is well known fact that the surface area of wet lump increases as the size of lump decreases. The wet cake is disintegrated into fines to increase the surface area.

Ring Dryers incorporate a centrifugal classifier giving selective internal recirculation of semi-dried solids effectively lengthening the retention time of larger particles in the dryer while finer material, which dries more rapidly, exits the dryer with the exhaust air.

The classifier uses the centrifugal forces created through passing a product containing airstream around a curve to concentrate the product into a moving layer. The adjustable splitter blades are used to cut this layer and return the heavier, semi-dried material back to the dryer for another pass through the system while the lighter, drier product exits the dryer and gets conveyed to the product collection system. Manifolds can have single or multi classification blades and are often used in combination with disintegrators for greater control of particle size, product moisture and exhaust temperature.

What our Customers say

What our Customers say