Martin Method

MARTIN PROCESS is one of the old and common wheat starch production processes in the world. This method is modified different times to get a better result. Many companies based on their experience in production, changed the MARTIN PROCESS to fit their requirements.

Advanced MARTIN PROCESS is the most common process recently used in many factories around the globe.

Advantages of Advanced MARTIN PROCESS:

1- Easy to operate

2- Requires low investment

3- Good for small production line

Here is a brief review of main stages in Advanced MARTIN PROCESS for wheat starch production:

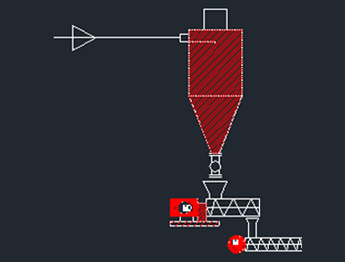

1- Mixing flour and Water

Flour is fed to flour storage silo. Flour goes to mixing machine by means of air conveyor system .Flour and water mixed in the mixing machine with a certain ratio.

Flour is fed to flour storage silo. Flour goes to mixing machine by means of air conveyor system .Flour and water mixed in the mixing machine with a certain ratio.

The slurry is transferred to slurry washing machine where washing carried out and gluten structure forms.

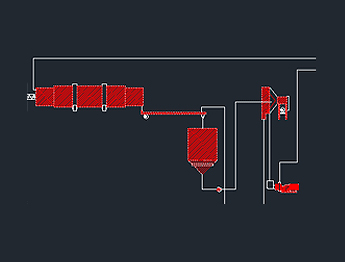

2- Starch and Gluten Separation

Gluten lump forms in the slurry washing machine then gluten and starch slurry discharghed on the top of vibration sieve. Gluten lump goes to gluten washing machine then dewatered by means of screw press to be dried by a ring air-flow dryer.

Gluten lump forms in the slurry washing machine then gluten and starch slurry discharghed on the top of vibration sieve. Gluten lump goes to gluten washing machine then dewatered by means of screw press to be dried by a ring air-flow dryer.

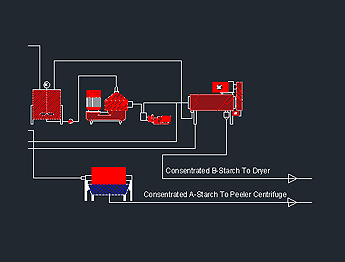

Starch slurry goes to a set of rotary sieves for fiber and starch separation. Fiber is dried to be used for animal feed and starch slurry goes to a disc separator for A-starch and B-starch separation.

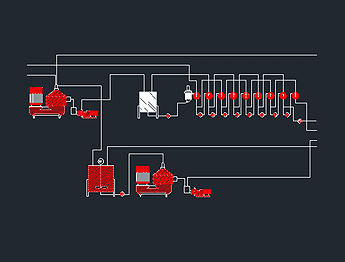

3- Starch Washing and Concentration

A-starch and B-starch are separated by means of a centrifugal disc separator. B-starch is concentarted by means of a high speed disc separator . A-starch goes to Hydrocylone units for washing and concentration.

A-starch and B-starch are separated by means of a centrifugal disc separator. B-starch is concentarted by means of a high speed disc separator . A-starch goes to Hydrocylone units for washing and concentration.

4- Starch Dewatering and Drying

B-starch is concentrated by means of a centrifuge decanter and leaves decanter to air-flash dryer.

B-starch is concentrated by means of a centrifuge decanter and leaves decanter to air-flash dryer.

Concentrated A-starch leaves hydrocyclones units to a dewatering machine. Dewatered A-starch goes to a air-flow dryer by means of a screw conveyor.

What our Customers say

What our Customers say